1. The usual maintenance did not keep up, causing the pump to malfunction.

The main reason for the swinging of the swing cylinder and the S swing valve is because the tightened nut is detached. This also indicates that there is a lack of maintenance and overhaul of this pump truck. Such faults generally do not occur if checked frequently.

2. Lack of emergency treatment experience, causing concrete condensation in the pipe

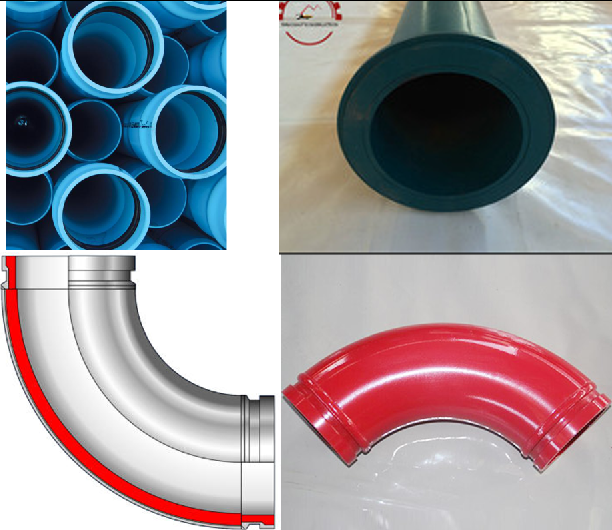

Generally, after the pump fails and cannot be pumped, it can not be repaired in a short time. The mixer pump should immediately empty the concrete in the conveying pipe. Otherwise, the concrete pump will cause the waste pipe to be scrapped. When the concrete is also fluid, the elbow behind the hopper is disassembled, and the boom is vertically discharged from the conveying pipe by the gravity of the concrete itself. However, the concrete in the flat pipe, the emergency treatment after the obstacle still needs to be dismantled and manually discharged.

If the above method can not automatically discharge the concrete inside the pipe, you can start the pipe from the back pipe and remove the pipe in the direction of the boom to minimize the blockage length of the pipe and reduce the loss and the later work. However, be careful to flatten the boom when dismantling the pipe to prevent the concrete from being sprayed and hurting people due to gravity.Our company is concrete pump parts sellers and can provide concrete delivery pipe,you can buy it.

What is the cause of the flow interruption in concrete pump trucks?

The turbulent flow of the concrete pump truck during each commutation process usually shows a significant flow-break-flow phenomenon, which is commonly referred to as the current interruption phenomenon.

here are three reasons for the flow phenomenon:

1 When the main cylinder runs to the end of the stroke, the commutation signal is sent to the reversing cylinder for reversing, and then the main system oil passage is reversed, and the main cylinder moves in the opposite direction, the process takes at least 0.2s;

2) The inhalation efficiency of the inhaled cylinder is usually only 85% to 95%, inevitably inhaling a small amount of air, which will be a short flight;

3 When the reversing cylinder is in the direction of outward output, the pressure is increased and there is a certain compressibility, which is also a short flight. Due to the commutation and the two-stage idle travel time, the concrete pump truck appeared and there was a problem of current interruption during the pumping process. Continuous pumping is achieved prior to complete release of the helium pressure in the piping and distribution valves to minimize the counter-impact of the turbulent pressure release in the piping and distribution valves during shut-off separation and reversing. Through the selection and setting of the control mode of the main oil pump, the problem of interrupted flow of the helium transport can be effectively solved, the commutation shock is reduced, and the pumping performance of the helium pump is greatly improved.